When I first meet a new devotee to tailoring and in some cases experienced veterans I always like to ask “what they know about cloth and how it performs?” This is part of my usual grilling process to find out exactly what our clients want to achieve when they choose to use Redmayne’s bespoke or made to measure tailoring service. You see we’re not here just to sell suits we want you for life. Sounds a little bold but why not. If we can truly know your needs then we can truly look after you. So back to my question “what do you know about cloth Sir”? This is usually met with a blank face and a momentary twinge of embarrassment as the client realises they usually don’t have a clue. Well, don’t worry you’re not supposed to, as any decent tailoring house should advise you honestly and not just simply try to empty your pockets, I’m going to try to help you a little as clearly as possible with a few words from an expert in the cloth business. I last wrote about how to understand cloths about about fifteen years ago. The good news is that what we had then is still available but now things have got even more interesting. All sorts are now being woven into cloth. Bamboo and sapphire particles for instance…and no, I’m not kidding.

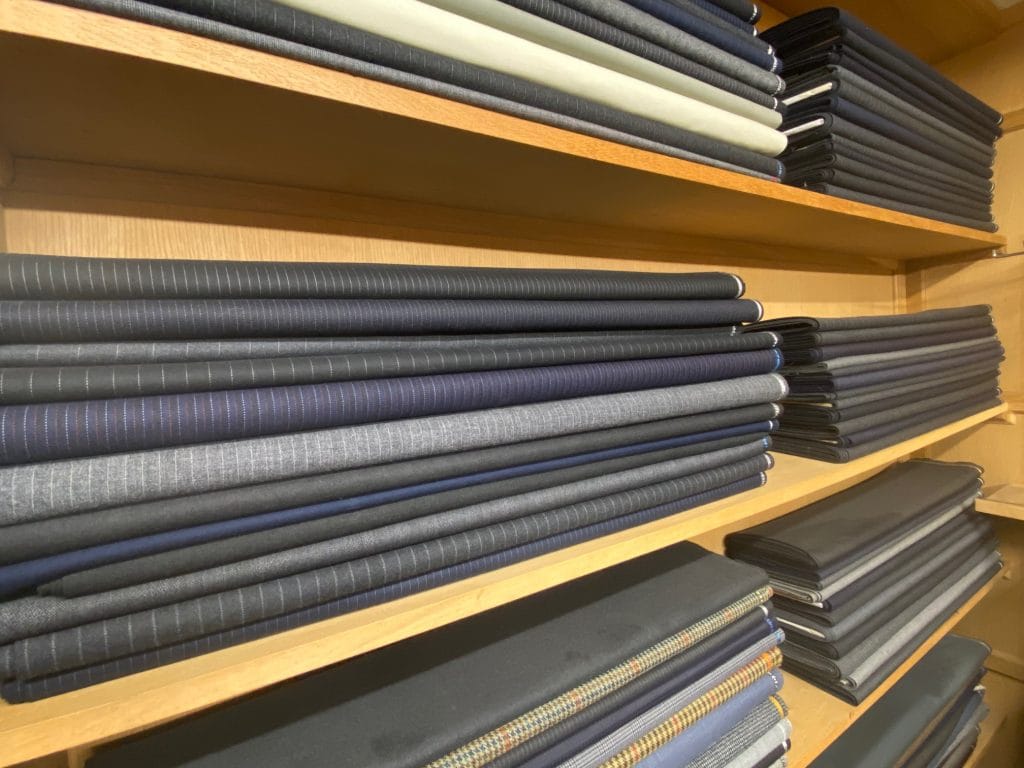

OK, There’s a lot of cloth out there, made into ready to wear garments by the thousands and bespoke and made to measure tailoring. They range from inexpensive Asian cloths to super exclusive vicunas, cashmere’s and super 260’s. So let’s start with telling you about a tailors go to choice of cloth used in about 80% of Savile Row bespoke and quality made to measure tailoring. Classic English “Worsted” is the answer, usually made in Yorkshire, England the home of fabric weaving in the UK for centuries. They range from large and small weavers but these mills have earned respect from around world and rightly so.

Worsted’s are usually made from Merino wool (which usually means Australian and New Zealand Merino sheep fleeces) and they’re supplied by all the London cloth merchants and directly from some the mills in what we call full pieces (60 – 65 meters of one design). It would be lovely to say we used British wool but it’s usually a little firm. On the flip side it’s tuff, probably due to our climate so you will find it in clothing but usually only in tweeds for the great outdoors. And again, because of its strength you’ll find carpets, heat insulation and more heavy duty applications.

Tailors love English worsted’s, ideally about the 11 oz ( 310-15 grams) weight. The reason is these cloths make up very well and with a little care they can last for decades. These are the cloths that tailor and wear well. On a purely selfish note tailors and cloth salesmen know that these are always a safe bet. As I always say, ” get the tailoring right and you’ll never fall out of love with these cloths” People come back time and time again and many times a client will simply ask me to replace an old favourite as they’re usually in a traditional design and something very similar is usually available. Many fabrics look the same but the qualities and prices can vary a lot which is why I’ll try to keep this simple to help you understand the fabrics used in bespoke and made to measure suits. Marketing is a powerful thing so let’s see if we can show you what you should be looking for, instead of being dazed by lots of terms such as “super quality” and “exclusive” which usually have an exclusive price tag to match. So does “quality” mean texture and design? Or is it about durability and longevity? Remember that suits and therefore cloth should be commissioned for a reason, not a whim. So like everything in life a little research can help you avoid a lot of disappointment. Worsted cloth is rated by numbers. Super 120’s, Super 150’s and now Super 250’s for example. Sometimes they also rate the type of fleece or rarer yarns such as Lessers Golden Bale. So what does all this mean? These numbers refer to the count, or fineness of the yarn used in the cloth. The finer the count (yarn measured in microns) the finer and softer the handle of the cloth. In very basic terms a fine yarn is smoother and finer as you’d expect. A lower count has not been spun so finely and is therefore thicker and stronger but not so soft to handle. To qualify as a traditionally accepted wool worsted the fabric is usually rated as a super 90’s quality or above. It normally would say on the pattern bunch but if it’s from a reputable company you can presume a figure between 90 and 100. It’s only when you go higher up the quality ladder that they start blowing their trumpet such as Super 120’s etc right up to the dizzy heights of super 250’s.

The Super 150’s and higher are indeed beautiful cloths, but there’s a price to pay which is not only financial. They do feel wonderful to handle but the simple fact is they don’t always wear so well, especially if you combine this quality in a light weight. Admittedly, in my thirty years or so in the trade the weavers have done some magic and their skills and have improved how these super quality cloths handle but they’re generally not as durable as their lesser-numbered cousins. Remember, made to measure garments are made using very sophisticated kit. They can therefore make garments of very fine and lightweight quality. However, with bespoke you’re really paying for 300 year old technology. We don’t hand sew suits much differently now to what we did a couple of hundred years ago. Therein lies the problem, the technology of hand tailoring was devised when all cloths were heavy and sturdy, so there are limits for true bespoke hand tailoring. Don’t get me wrong, I’m not saying it cant be done but I live in the real world and I wouldn’t fancy making a 6.5 oz, super 200’s bespoke hand made suit in a hurry. By the way, when we talk durability some people will extol the virtues of a poly mix wool. OK they may work but my opinion… I’d rather not. I’m not bemoaning highly rated cloths but the reality is that it’s like the old business triangle equation. You can have either – “good, fast or cheap” – choose two? So with cloth you have – cost, durability and texture – you can choose two? Rather crude analogy but it holds pretty true. Still, if money is no object and you want to feel the finest stuff against your skin or impress the lady on your arm then choose a super 220’s with Sapphire shards. The shards bit sounds a bit contradictory but it works and don’t ask me how. And there you have it – handle (gorgeous), durable (maybe) but certainly not low cost.

The other advantage of high-number wool worsted’s is that because of the finer yarns used, the weavers seem to get more colours and intricate designs into the fabric which is not always to be said of the more classic quality’s. This can make them very tempting as you gaze and stroke them but remember you need deep pockets.

Rest assured, no Savile Row tailor or decent made to measure house is going to sell you an inferior cloth, as the result to his reputation would take a nosedive. But just remember the cost of cloth can differ vastly and it’s often for different reasons than you may think.

To try to summarise this, I always prefer English Worsted’s although I know Italian and Japanese cloths can also be excellent. Before any one starts writing, please remember this is my opinion and choice after a good few years in the trade. It’s information for you to use, enjoy or discard if you wish. Super numbers look and feel fantastic but don’t always wear well and they can add 20-30 or even 200% to the cost of your suit so be aware of what’s driving your choice. Your more affordable, classic worsted’s are usually made into the timeless designs- solid blues and greys, pin and chalk stripes etc. So you’ll always have room for them in your wardrobe and they’ll always make up well and last for years. If there is a downside, the designs are usually a little more standardised. A word of advice. It’s very easy for some obscure manufacturer to produce a sample bunch with all sorts of fancy numbers and claims on it. And if they’re being frugal with the truth then you’ll find out the hard way, usually a year down the line when the suit starts shining with wear and generally loosing its shape. No tailor knows all of the manufacturers in the world but look out for these familiar names and you wont go far wrong.

Holland & Sherry and Harrison’s for example, couple of merchants that have a huge selection of great trustworthy cloths. Huddersfield fine Worsted’s are a good choice also. If you want good reliable exclusive cloths then look into Dormeuil and Scabal.

Other suppliers such as Dugdale Bros and Fox Brothers are also excellent. Although fabric is obviously a huge part of any suit, when it comes to bespoke it’s relatively speaking, the smallest part in cost terms. It’s the hours of skilled work that you’re paying for. So I think its safer to get your cloth from your tailor unless you’re well experienced. This way you are protected as good tailoring houses shouldn’t take risks with you and ultimately their reputation.

I like to give freely what I know about my trade but I’m fortunate that I know people who are far more qualified than me and I can always call on them for help. Hence you’ve got about 60 seconds of wisdom above from Mark Dunsford. We’ve been friends for about twenty odd years and his company, Harrisons of Edinburgh is one of the leaders in the cloth trade. He knows his stuff, so I’d listen up.

The poor chap thought I was dropping in to see him for a pint but I asked him for an impromptu few words of advice regarding cloth. It’s not very polished but it’s honest and from someone who really knows. I’m in the suit business not the film business after all. Thanks Mark and I promise you a pint next time.

Leave a Reply

About Tom

Tom has been involved at the highest level in the tailoring industry for over 37 years. He has also been blogging and furthering knowledge of the craft for over 15 years. He is married to Claire and has three children.